WHEN SHOULD I USE DUCTILE IRON PILES?

If your project has:

Limited access, small laydown areas or variable platform levels

Vibration sensitivity

Low overhead clearance restrictions (4m and above)

Additions to existing buildings

Deep or undulating bearing layers requiring pile splicing or slow pile installation

If one or more of the following Challenges are encountered:

Poor soil conditions – deep soft soils, fill material, organic materials or contaminated fill

Structures sensitive to vibration

Adjacent structures

Difficult access and constrained sites

Low overhead

Variable levels of site

If you are considering these techniques for your project:

Mini Piles

Screw piles

Short piles where reduced installation vibration, speed of installation or constrained site footprint makes DIPPS a good solution

Long piles where elimination of slow splicing or working with short sections maximises the benefit

BENEFITS OF DUCTILE IRON PILES:

Safe:

The Ductile Iron Pipe Piles are driven into the ground and effectively transmit the forces from the building or bridge structure into the load bearing strata in the ground.

The equipment used is light weight and mobile using excavators as the base machine to carry the high frequency percussive piling hammer.

The use of excavators rather than traditional fixed leader piling rigs with vertical masts allows smaller working platforms and access tracks which do not have to be engineered to the high standard required by the fixed leader rigs. The risk of rig overturning is substantially reduced.

The working platform and access are made suitable for a 20 - 40 ton excavator and 5m3 ready mix truck. As there is no fixed leader with drive motor / hammer at height causing high overturning loads the platform does not have to be engineered and certified. The excavator can cope with different levels in the platform if required.

The piles are supplied in 5m sections for easy and safe handling.

The short pile length reduces the fall radius and exclusion zones required. The operators cab is normally outside the fall radius.

The spigot pile joint results in a positive joint with immediate capacity thus minimising any risk of the upper section falling.

The joint does not require completion by the site crew eliminating exposure of the crew to falling piles or hammers.

Only a small crew is required to install the Ductile Iron Pipe piles leading to a reduced exposure to any hazards on site.

The excavator boom allows the base machine to stand back from the pile being driven allowing piles to be driven downslope on embankments without the requirement for multiple working platforms or the rig accessing the slope.

Cost Effective

Often provide 15-25% cost savings over mini piles and other deep foundation systems

Depth Flexibility

The Plug & Drive System allows for easy length adjustments in the field when faced with fluctuating bearing layer depths. The system can easily be installed to 20 feet or more than 100 feet by simply adding additional DIP sections with the Plug & Drive moment-resisting, drive-on connection

Easy Access

Mobile relatively light track mounted equipment and modular pile sections allow for rapid work in limited access, constrained sites, sloping ground and small laydown areas. The 20 – 40 Mt base machine and 5m long pile sections only need a small crew to handle and install the piles reducing the size of the working platform required for the equipment to operate on

TYPICAL APPLICATIONS:

Minimal Waste

The system generates virtually no waste since the cut off section of the pile is used as the starter pile for the next location. This is a significant advantage over traditional steel piles (pipe or H-piles) on sites with varying founding levels which would result in wasted cut-off material or having to wait for costly field splicing. Ductile Iron Pipe Piles eliminate these concerns completely.

High Load Capacity

Working capacities range from 25 – to more than 100 Mt in compression and often up to 50 Mt in tension

Quality Installation

Load bearing capacity and pile length are determined on site through monitoring of penetration resistance during driving, measurement of set and confirmation of capacity with PDA testing

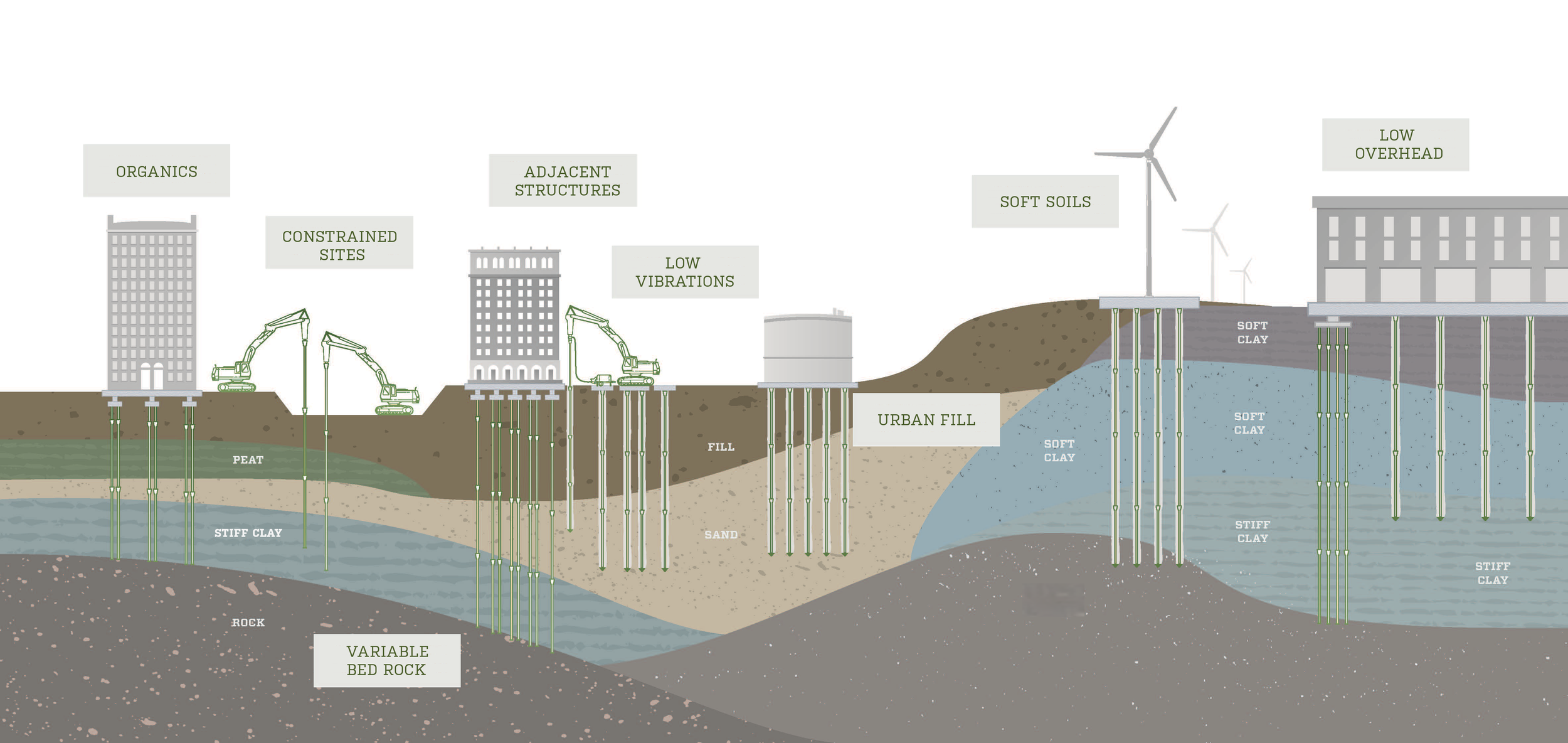

Ductile Iron Pipe Piles provide reliable support for commercial, industrial, residential and infrastructure projects including new construction, additions to existing facilities and interior retrofit applications. Ductile Iron Pipe Piles provide cost-effective deep foundation solutions for foundation and floor slab support to resist compression, tension and lateral loads. The system offers low cost high value solutions for the following challenges:

Low Headroom

Deep foundation options for interior applications are often limited due to access and overhead obstructions. Ductile Iron Pipe Piles are uniquely positioned to provide a rapid, cost-effective solution for interior work in commercial, industrial, warehousing and other applications. Ductile Iron Pipe Piles are a modular system with pile sections that are typically between 5.0 to 5.5 metres in length. The innovative Plug and Drive (bell – spigot) joint allows rapid connection of piles to achieve substantial depths even with limited overhead clearance. Further, pile sections can be cut in half or thirds and connected with drive-on couplers to allow work in severely limited overhead conditions. Installers of the Ductile Iron Pipe Pile systems routinely work within overhead clearances of 4m or above. By providing higher capacities than light-duty screw piles and less cost and faster installations than large diameter screw piles and mini piles, Ductile Iron Pipe Piles offer a low cost high value deep foundation option when working in low-overhead conditions.

Low Vibration

High frequency low amplitude driving energy results in low vibrations during installation occurring within and adjacent to existing structures

Soft Soils

Deep foundations have long been used to penetrate and bypass soft soils to prevent unacceptable settlement or even bearing capacity failure of supported structures. Ductile Iron Pipe Piles are driven rapidly through soft soils to transfer structural loads to underlying stronger soils and, in some cases, can be advanced (pushed) using only the weight and crowd force of the excavator and percussion hammer. Ductile Iron Pipe Piles are specifically designed to resist buckling of the pile surrounded by soft layers at design loads typically ranging from 25 to 100 tons. The monitoring of pile penetration resistance during driving allows for the detection of the soft zone and to verify that the piles develop capacity in the competent ground conditions below soft zones of soil. With the modular nature of Ductile Iron Pipe Piles, adding pile lengths to penetrate deeper than anticipated soft zones is easily achieved by adding pile sections using the rapid, moment resisting Plug and Drive connection. This eliminates the need for time consuming mechanical splicing or welding additional pile sections that would be required with traditional driven pile methods.

Urban Fill

Development of urban properties is often complicated by the presence of urban fill below grade. Remnants of past structures on the site often result in obstructions buried within the fill, such as pieces of concrete, brick, wood, and various other items. Common remedies include removal and replacement of the unsuitable soils, ground improvement, or deep foundations. Removal and replacement often requires extensive support of the excavation to avoid impacts to adjacent structures and may require expensive handling of contaminated soils. Traditional deep foundations or ground improvement must penetrate the urban fill and may require expensive drilling equipment capable of delivering high-torque drilling for larger diameter pile elements. In many cases, the cost for pre-drilling to penetrate and create a clear path for foundation elements drives foundation costs to extreme levels. Small diameter Ductile Iron Piles driven with high frequency, percussion energy have a track record for successful installations on fill sites where the piles effectively displace small obstructions and penetrate the urban fill. When pre-drilling is required, the pre-drilled diameters for Ductile Iron Pipe Piles are much smaller than pre-drill diameters required for other foundation elements, resulting in smaller size equipment requirements, less effort, and less cost. Additionally, when unexpected obstructions are encountered at sites that result in shallow pile refusal, the modular Ductile Iron Pipe Pile system results in less waste if a refused pile must be abandoned. New offset pile locations can easily be started with the remaining, above ground portion of any abandoned Ductile Iron Pipe Pile location.

Variable Bedrock

In many geologies, the strength and elevation of competent bedrock makes for great uncertainty in the predicted lengths of deep foundation systems. This is particularly challenging for driven pile systems, which are commonly ordered and delivered in pre-determined lengths. Changes in the bedrock elevation can often result in the need for waiting for additional material combined with slow and costly field splicing when the bearing strata is deep. Alternatively, significant wasted pile material can result when shallow rock is encountered, and excessive pile lengths are required to be cut off. These risks are substantially reduced with Ductile Iron Pipe Piles – a modular system with pile sections that are typically between 5.0 to 5.5 meters in length. The innovative Plug and Drive (bell – spigot) joint allows easy and rapid connection of pile sections to achieve virtually any length and eliminates field splicing to easily solve the issue of longer piles. Further, the modular nature of Ductile Iron Pipe Piles significantly reduces the risk associated with large amounts of pile waste. When piles reach early refusal or “set,” the remaining section of pile is cut off and used as a starter pile section on the next pile location, thereby eliminating the material waste. Unused pile sections can also be easily re-used on future jobs to allow Specialist Piling Contractors to have confidence in ordering materials. For sites with variable bedrock, Ductile Iron Pipe Piles greatly reduce material waste and lead to the efficient use of pile materials.

Low Vibrations

Ductile Iron Pipe Piles are ideally suited for urban conditions or interior construction where vibration levels are a concern. Traditional driven piles use large hammers that generate high amplitude and low frequency vibrations that travel long distances, often exceeding vibration thresholds and can cause vibration-related damage to nearby structures. Unlike traditional driven pile installation, Ductile Iron Pipe Piles are installed with a standard high frequency percussion hammer. The percussion hammer delivers high frequency, low amplitude vibration levels. The hammer energy levels are considerably less than those required for a traditional driven pile. Typical peak particle velocities often range from only 12 to 38 mm/second within a metre of installation and dissipate rapidly at distances of only 3 to 6 metres away from the installation. With these low vibration levels, Ductile Iron Pipe Piles are often a preferred approach for projects featuring building additions, urban construction and interior, low-overhead projects.

FREQUENTLY ASKED QUESTIONS:

Adjacent Structures

Construction of building additions often requires foundation systems capable of generating low vibrations during installation and working in close proximity to existing buildings for new foundation work. Ductile Iron Pipe Piles are installed using medium-sized excavators (i.e. 20 to 40 tons) that are able to manoeuver close to existing buildings on sites with tight access. Driving is performed using a percussion hammer that generates high frequency, low amplitude energy. The high frequency energy results in limited vibrations to facilitate pile installation adjacent to existing buildings. The combination of the ease of access and low vibrations make Ductile Iron Pipe Piles a good solution for new projects adjacent to existing structures.

Constrained Sites

Projects routinely require work on constrained sites including small site footprints in urban settings, at industrial or commercial facilities with obstructed access or sites requiring work at various platform levels. Ductile Iron Pipe Piles are a preferred solution to easily accommodate the various site constraint challenges. With the modular pile sections, transportation in small bundles makes for ease of delivery and stacking on tight sites to limit staging area needs. The modular pile sections incorporate the Plug and Drive connection to install piles to virtually any practical length while managing sections of less than 5.5 m in length, significantly reducing laydown requirements compared with traditional driven piles, drilled shafts or Continuous Flight Auger piles. The excavator/percussion hammer combination limits the amount of space required for equipment compared with other standard fixed leader / vertical mast rigs and allows easy manoeuvrability and the ability to install piles from various levels across the site. The low vibration levels during installation reduce the potential for damage during installation. For many reasons, Ductile Iron Pipe Piles offer significant benefits on these constrained, challenging sites.

Rapid Installation

Daily production rates range from 140 – 300 LnM per crew

Poor Ground Conditions

Soils (peat, organic materials silt/clay) are often soft and highly compressible and are subject to long-term secondary compression (settlement) and material degradation. Depths of soft deposits can be highly variable across a site and without extensive geotechnical investigation are often not discovered until foundation installation. Building sites with soft soils typically require deep foundations to transfer foundation and slab loads below the soft zones. Ductile Iron Pipe Piles have been used extensively on sites with soft soils. The Ductile Iron Pipe Piles are designed to resist buckling of the pile in the soft layer. The monitoring of pile penetration resistance during driving allows for the detection of the extent of the soft zone and verification of the piles developed capacity in the competent ground conditions below the soft material. With the modular nature of the piles, additional pile length required to penetrate deeper than anticipated soft zones is easily achieved by adding pile sections using the rapid installation, moment resisting Plug and Drive connection.

-

Ductile Iron Pipe Piles (DIPPS) are modular, low vibration driven piles manufactured from ductile iron using a centrifugal-casting process. With the standard DIPPS section length of 5 m, the piles employ a unique Plug & Drive connection system enabling additional pile lengths to be quickly added without added mechanical connections or field splicing. Piles of varying lengths can be driven to depth and the cut-off section is used as the lead section for the next pile, resulting in minimal or no waste of pile material.

-

Tens of millions of metres of DIPPS have been installed throughout the world over the past three decades in Europe, USA, Canada, South America, South Africa, Australia. Ductile Piling Solutions specialises in Ductile Iron Pipe Pile projects in Australia, New Zealand and the South Pacific where DIPPS have been installed for over 20 years.

-

If your project has:

Tight access, limited laydown area or variable levels

Vibration-sensitivity

Low overhead clearance restrictions (5m and above)

Building additions

Deep bearing layers that result in pile splicing or slow pile installation

You are considering the following techniques:

Mini piles

Screw piles

Short piles where reduced installation vibrations, speed of installation or constrained site footprint makes DIPPS a good solution

Long piles where elimination of time consuming splicing or working with short pile sections maximises the benefit of the DIPPS solution

The site has one or more of the following challenges:

Poor soil conditions – deep soft soils, fills and/or organic materials

Vibration sensitivity

Adjacent structures

Difficult access and constrained sites

Low overhead

Variable levels

-

Cost-Effective: Often provide 15-25% cost savings over drilled mini piles and often other traditional deep foundation systems

Rapid Installation: Daily production rates typically range from 140 to more than 300 metres per crew

Low Vibration: High-frequency driving process results in low vibrations allowing installation to occur within or adjacent to existing structures

High Load-Carrying Capacity: Working capacities range from 25 to more than 100 tons in compression, and often up to 50 Mt in tension

Flexibility: The Plug & Drive connection system allows for easy pile length adjustments in the field when faced with fluctuating bearing layer depths

Easy Access: Track mounted mobile equipment and short pile sections allow for rapid work on constrained sites, variable working platform levels and limited laydown areas

Minimal Waste: Once completed, the pile is cut-off and the cut-off section including the bell is used as the starter pile for the next location, resulting in virtually no waste

Quality Installation: Pile capacity and length are determined on-site through monitoring of pile penetration resistance during driving and confirmed by load testing

-

Building Foundations

Floor slabs

Tension Piles

Infrastructure Foundations

Tank base supports

Solar panel installations

Wind Turbine footings

Underpinning of structures

-

Ductile Iron Pipe Piles are used to resist both compression and tension loads. Compression loads are resisted through either end-bearing on dense/hard soil or rock or alternatively through frictional resistance developed with a grout-to-ground bond zone within competent material. This bond zone is created when the Ductile Iron Pipe Pile is driven with a patented oversized grout cap and grout is simultaneously pumped during driving to fill the annular space. Tension loads are resisted using the same grout-to-ground frictional mechanism engaged in tension by using a high-strength threaded reinforcing bar centralized in the pile as a reaction to resist uplift loads.

-

Ductile Iron Pipe Piles are well-suited for supporting loads in a variety of problematic soil conditions including both cohesive and non-cohesive soils. Typical geotechnical conditions requiring the use of Ductile Iron Pipe Piles consist of:

loose or soft undocumented fill

loose sand to medium dense sand

soft and compressible clay and silt

peat and organic materials

The DIPPs are designed and installed to penetrate these problematic soil conditions and develop resistance through either end-bearing on competent soil or rock or through frictional resistance afforded by a grouted bond zone formed along the portion of the pile installed in the competent soils. Ductile Iron Pipe Piles developing capacity in end-bearing are installed to achieve a particular “set” criteria while penetrating into a dense layer (i.e. very dense sand, sandstone, hard clay, etc) or refusal on rock. Friction DIPPs require the presence of a dense to very dense granular soil or firm to hard cohesive soil to develop a grouted bond zone capable of providing sufficient frictional resistance with the soil to achieve the design capacity.

-

Allowable skin friction values for the grout-to-ground interface depend on the specific soil condition in which the bond is being developed as well as the consistency or density of the layer. The figures developed by the pile manufacturer from decades of load test experience provide approximate ranges of skin friction values for cohesive and non-cohesive soil layers.

-

Yes, DIPPs do offer superior corrosion resistance. The materials used to manufacture the pile contain higher silicon and carbon contents when compared to traditional steel products, resulting in greater corrosion resistance. The excess carbon acts as a filtering mesh preventing corrosion penetration, while the silicon causes the formation of a durable protective iron silicate outer layer. Sacrificial corrosion rates are well established in the Austrian standard ONR 22567 (as determined by MA39, i.e. Material Testing Authorities, Vienna). Ductile Iron Pipe Pile designs must consider the corrosion susceptibility of a site and either reduce the allowable design values based on a reduced pile sectional area (i.e. sacrificial layer) or incorporate exterior grout to reduce corrosion concerns.

-

DIPPs are installed using a hydraulic hammer that delivers high-frequency, low-amplitude impact ramming energy during the driving process. The high frequency energy combined with the penetration of relatively small diameter DIPPs result in low vibrations that dissipate rapidly during driving. Vibration monitoring on typical sites show peak particle velocities on the order of 12 to 38 mm/second within a metre of the pile installation. These vibration levels dissipate rapidly at distances of only 3 to 6m and are often not perceptible at short distances away from the installation. Many DIPP projects have been successfully completed with installation occurring within existing (and active) facilities and within 450 mm of existing buildings. The limitation is often more related to equipment access than vibrations during installation. Sound levels are comparable with other earthwork equipment operations.

-

Ductile Iron Pipe Piles are often a preferred solution on constrained sites for multiple reasons. Transportation and staging of the piles is easily managed because the 5m standard lengths allow easy delivery access in urban environments and limited laydown requirements. The single piece of tracked equipment can operate within limited access areas, within excavations or within working platforms with varying levels. As a result, DIPPS are an ideal solution for constrained sites or those challenged with access issues. Further, the system is often installed in areas with low overhead conditions. The pile sections can be cut in half or thirds and a drive-on coupler is used to create a moment resisting connection, allowing the piles to be installed in 5m or greater overhead clearance. The system is often a preferred approach in low overhead conditions like warehouses, industrial facilities and commercial buildings because of the speed of installation and high capacities combined with the clean installation process and low vibrations.

-

Ductile Piling Solutions representatives would be pleased to provide technical feasibility and constructability assessments to evaluate whether Ductile Iron Pipe Piles are a good match for your project. Our engineers can assist you with preliminary feasibility designs based on geotechnical information and structural plans. You can contact us by email at:

info@ductilepilingsolutions.com

or call us directly at (+61) 0407 753 815

-

Ductile Iron Pipe Pile project design and installation is handled through Ductile Piling Solutions network of regional designers and installers. If you are interested in evaluating Ductile Iron Pipe Piles for your project, receiving a proposal for installation or interested in learning more about designing or installing the system, please contact us by email at:

info@ductilepilingsolutions.com

or call us directly at (+61) 0407 753 815

-

Ductile Piling Solutions is the distributor of TRM’s Ductile Iron Pipe Piles in Australia, New Zealand and the South Pacific. We continue to partner with leading engineers and Specialist Piling Contractors in Australia and New Zealand who specialise in DIPP design and installation, providing customers with efficient, cost-effective deep foundation alternatives for their projects. Ductile Piling Solutions works closely with all of our customers including Geotechnical Engineers, Structural Engineers, Architects, Asset Owners and Main Contractors to evaluate and establish the feasibility of the Ductile Iron Pipe Pile system. As projects evolve, we work closely with our DIPP Designers and Installers to provide technical, construction and testing support to ensure that proper design and installation methods are executed and the completed installation is fit for purpose.